First X-ray machine’s commissioning milestone marks start of research phase for one-of-a-kind lab

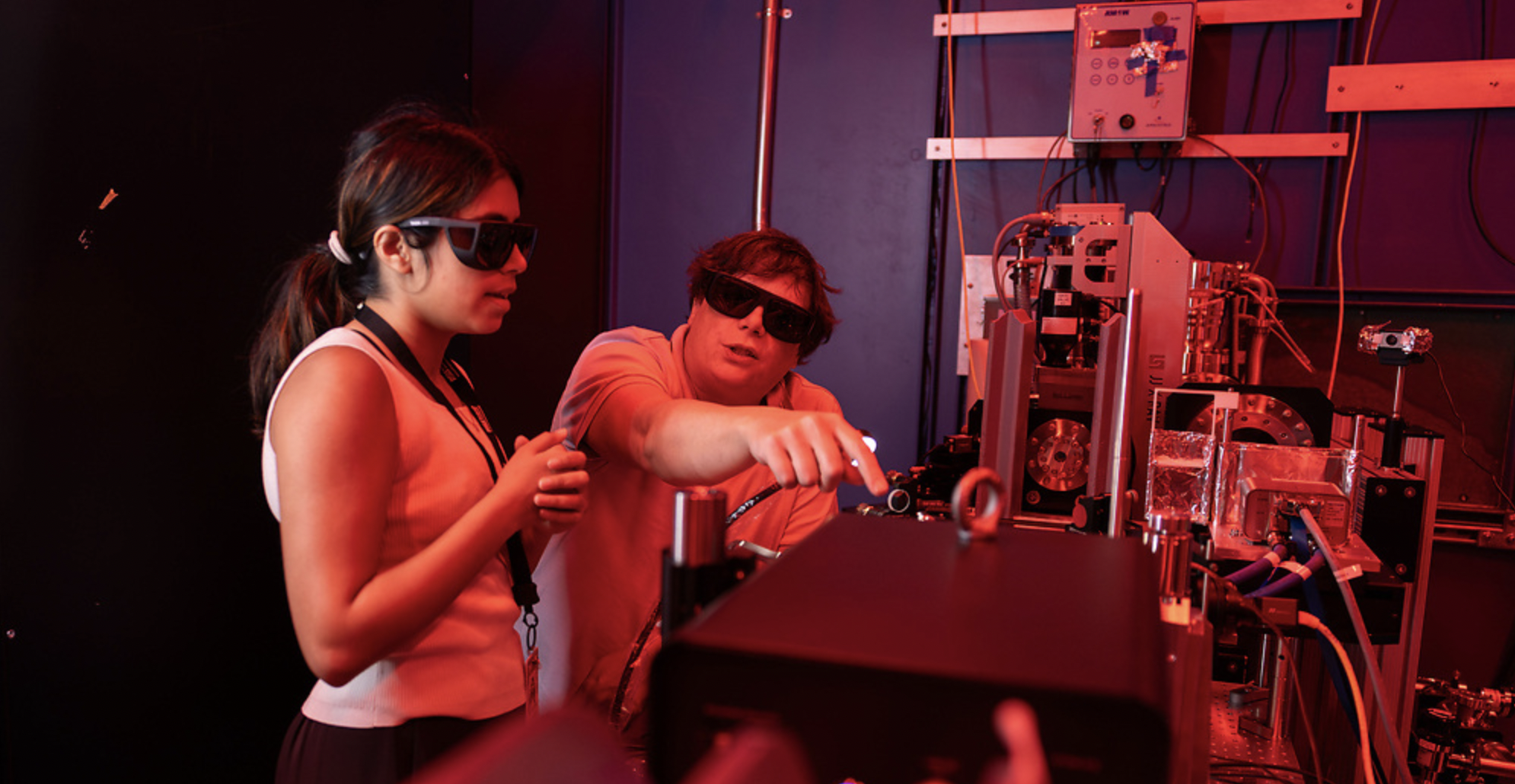

ASU electrical engineering graduate student Shreya Tripathi (left) and Research Scientist Aaron LaForge work in the sample hutch of the CXFEL Lab in Tempe on Aug. 27. Photo by Samantha Chow/Arizona State University

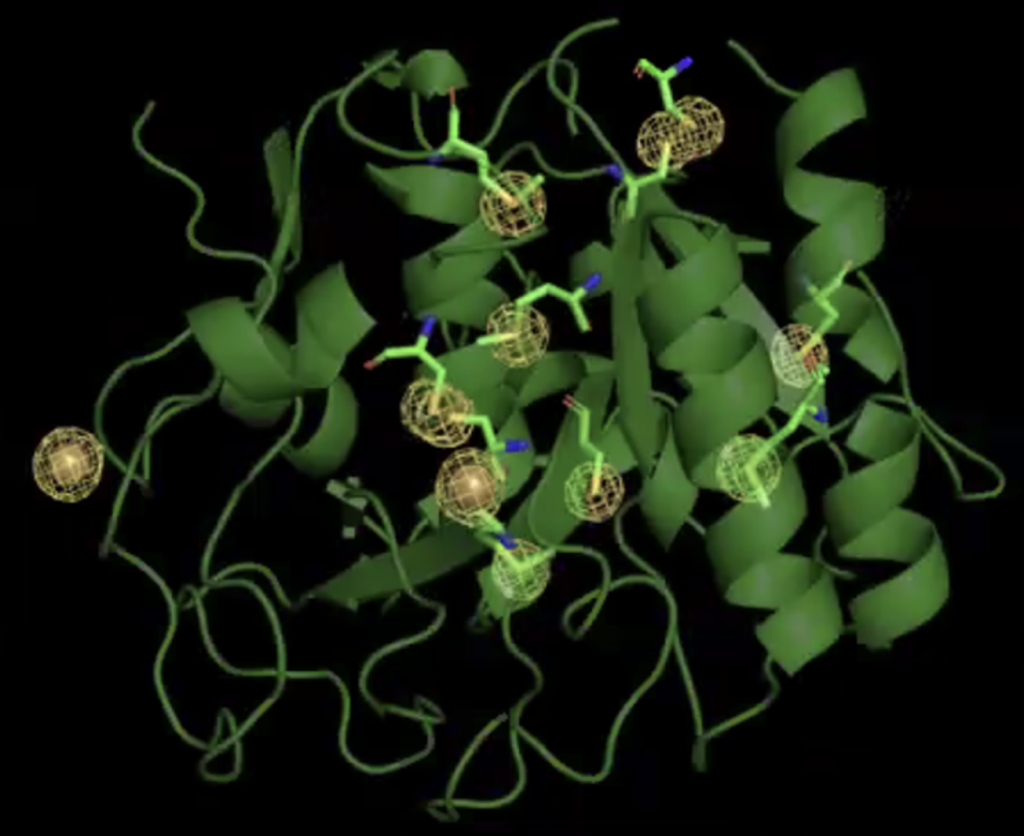

Now, Arizona State University scientists have successfully completed a series of commissioning experiments to solve their very first protein structure on a one-of-a-kind X-ray instrument: the compact X-ray light source (CXLS). This marks a major milestone in the opening of what promises to be the dawn of a new era of scientific discovery and its downstream applications to improve the health and well-being of society.

“Our goal is to make a world-class, compact X-ray facility, which will transform the way we study proteins, perform medical imaging and control quantum processes,” said Arvinder Sandhu, an ASU physics professor and recently appointed director of the CXFEL lab, housed at ASU’s Biodesign Institute.

Such power could lead to the discovery of better drugs with fewer side effects, improve medical imaging technologies, aid semiconductor manufacturing to build ever more powerful chips or quantum materials, and lead to more eco-friendly bioenergy applications.

“One of the most exciting applications of this new instrument will be its ability to examine proteins and determine what they do and how they do it,” said Josh LaBaer, Biodesign Institute executive director and proteomics expert who specializes in a field called personalized medicine, which uses a patient’s proteins as early diagnostic indicators or new therapies for disease.

A big idea: Make it small

In 2012, an ASU team helped pioneer the first adaptation of giant particle accelerators, called X-ray free electron lasers, or XFELs, to generate powerful X-rays that look into the heart of proteins.

Currently, there are only five X-ray free electron lasers in the world. These massive facilities — some stretching nearly 2 kilometers, with one spanning underground between two German cities — are booked years in advance, giving scientists just a few costly hours to conduct experiments.

“Our answer was to bring the accelerator XFEL technology to the lab by shrinking the XFEL and building the world’s first compact X-ray accelerators at ASU,” said Petra Fromme, the scientific director of the compact X-ray free electron laser (CXFEL) project and director of the Biodesign Center for Applied Structural Discoveries.

So, over the past decade, under the direction of former chief scientist and recently retired William Graves (who first dreamed up the technology), ASU has constructed a new building to house a world-class compact X-ray facility. Deep in the basement of the Biodesign Institute lies the main X-ray vault, sealed inside a custom cement facility. Six-foot-thick walls block vibrations, while a Faraday cage shuts out electronic interference. Behind a 30,000-lb. safety door to the vault is the recently completed 60-foot long CXLS, the first of two master-planned X-ray instruments.

Over the summer, a team of scientists, postdocs, graduate students and summer interns have been steadily moving the project forward. They have been conducting a series of milestone-making commissioning experiments in order to determine whether the CXLS’s ability to study matter, and to solve the 3D arrangement of atoms in potentially any molecule, matches that of the big-dog, huge XFELs.

A decade in the making, it took an ASU scientific village to achieve the first X-ray instrument’s milestone. (Image: ASU News)

‘Boom. We got it’

The team started with a simple sample of aluminum, “because it’s impossible to miss,” said Sabine Botha, a research assistant professor in ASU’s Department of Physics.

Next came the first real test: introducing the very first molecular sample to the X-ray beam. For this experiment, they choose a ceramic material called lanthanum hexaboride.

“Lanthanum hexaboride is our calibration sample,” said Samuel Teitelbaum, an assistant professor of physics at ASU and quantum materials expert. “When you have a new machine, benchmark measurements on a sample you understand well are critical.”

Shortly thereafter, the first ripple-like diffraction signals from the detector began to display on computer screens of postdoc Adil Ansari and researcher Hao Hu as Teitelbaum and fellow physicist Aaron LaForge supervised.

Just like a stone jutting out of a lake splits the water waves in different directions, every molecule creates a unique X-ray pattern to help the scientists solve the arrangement of the atoms and lanthanum hexaboride’s 3D structure.

The test was a success.

“Boom. We got it,” said Teitelbaum, upon seeing the data. “As experimentalists, you don’t really believe it will work until you see it done. … But as soon as I saw those aluminum lanthanum hexaboride rings, I knew we could do great science with the CXLS.”

The ultimate test

After that initial success, the researchers wanted to up the ante with their first experiment of an organic compound, vitamin B12, the most chemically complex vitamin. After preparing a crystal of the vitamin, they once again were able to detect its diffraction patterns.

By Joe Caspermeyer | Arizona State University

SOURCE: https://news.asu.edu/20250926-science-and-technology-new-era-asu-xray-science-officially-begins